CONTACT

Tel: +86-318-5838088

Phone: +86-13703186739

E-mail: sales@xakychina.com

Address: Phase 2, Shuangbed Work Park, Jingzhou Town, Jingxian County, Hengshui City, Hebei Province

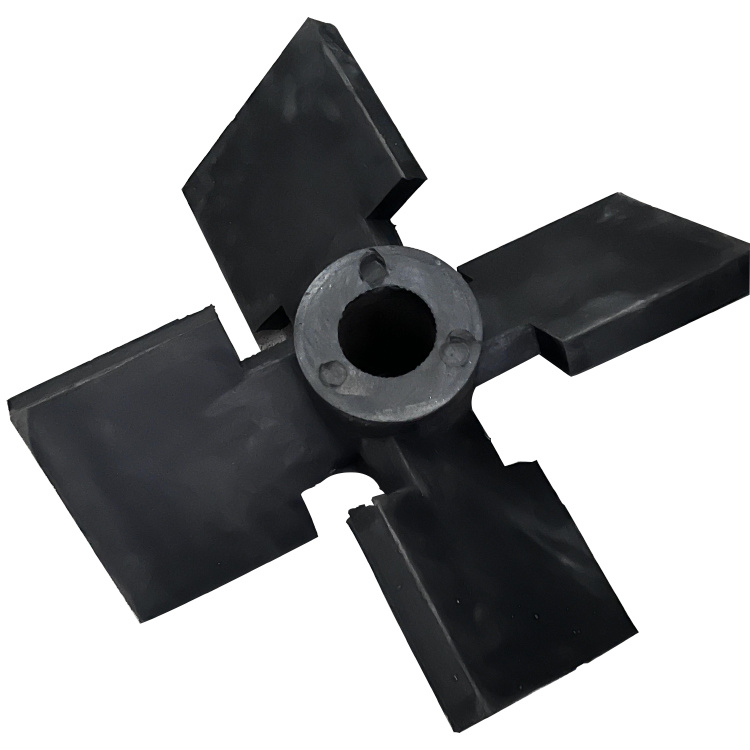

Polyurethane flotation machine rotor stator has both the high strength of plastic and the high elasticity of rubber. It is a new type of wear-resistant flotation machine rotor stator with excellent comprehensive performance.

The working principle of a flotation machine: When grinding or after grinding, add water and necessary reagents to form pulp through a stirring tank, and then inject them into the pulp tank where stirring begins. Introduce air into the pulp to form a large number of bubbles. Some mineral particles that are not easily wetted by water, commonly referred to as hydrophobic mineral particles, adhere to the bubbles and float together with the bubbles to the surface of the pulp, forming a mineralized bubble layer, while others that are easily wetted by water, That is, mineral particles commonly referred to as hydrophilic do not adhere to the bubbles, but remain in the pulp to discharge mineralized bubbles containing specific minerals, thereby achieving the purpose of mineral processing.

The working principle of a flotation machine: When grinding or after grinding, add water and necessary reagents to form pulp through a stirring tank, and then inject them into the pulp tank where stirring begins. Introduce air into the pulp to form a large number of bubbles. Some mineral particles that are not easily wetted by water, commonly referred to as hydrophobic mineral particles, adhere to the bubbles and float together with the bubbles to the surface of the pulp, forming a mineralized bubble layer, while others that are easily wetted by water, That is, mineral particles commonly referred to as hydrophilic do not adhere to the bubbles, but remain in the pulp to discharge mineralized bubbles containing specific minerals, thereby achieving the purpose of mineral processing.

The working principle of a flotation machine: When grinding or after grinding, add water and necessary reagents to form pulp through a stirring tank, and then inject them into the pulp tank where stirring begins. Introduce air into the pulp to form a large number of bubbles. Some mineral particles that are not easily wetted by water, commonly referred to as hydrophobic mineral particles, adhere to the bubbles and float together with the bubbles to the surface of the pulp, forming a mineralized bubble layer, while others that are easily wetted by water, That is, mineral particles commonly referred to as hydrophilic do not adhere to the bubbles, but remain in the pulp to discharge mineralized bubbles containing specific minerals, thereby achieving the purpose of mineral processing.

The flotation machine is mainly composed of a slurry bearing tank, a stirring device, an aeration device, and a device for discharging mineralized bubbles.

The flotation machine is mainly composed of a slurry bearing tank, a stirring device, an aeration device, and a device for discharging mineralized bubbles.

CONTACT XIN'AO

Tel: +86-318-5838088

Phone: +86-13703186739

E-mail: sales@xakychina.com

Address: Phase 2, Shuangbed Work Park, Jingzhou Town, Jingxian County, Hengshui City, Hebei Province

Mobile Web

Mobile Web

Copyright © 2022 Hengshui Xin'ao Mining & Metallurgy Rubber Products